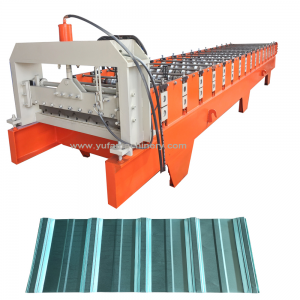

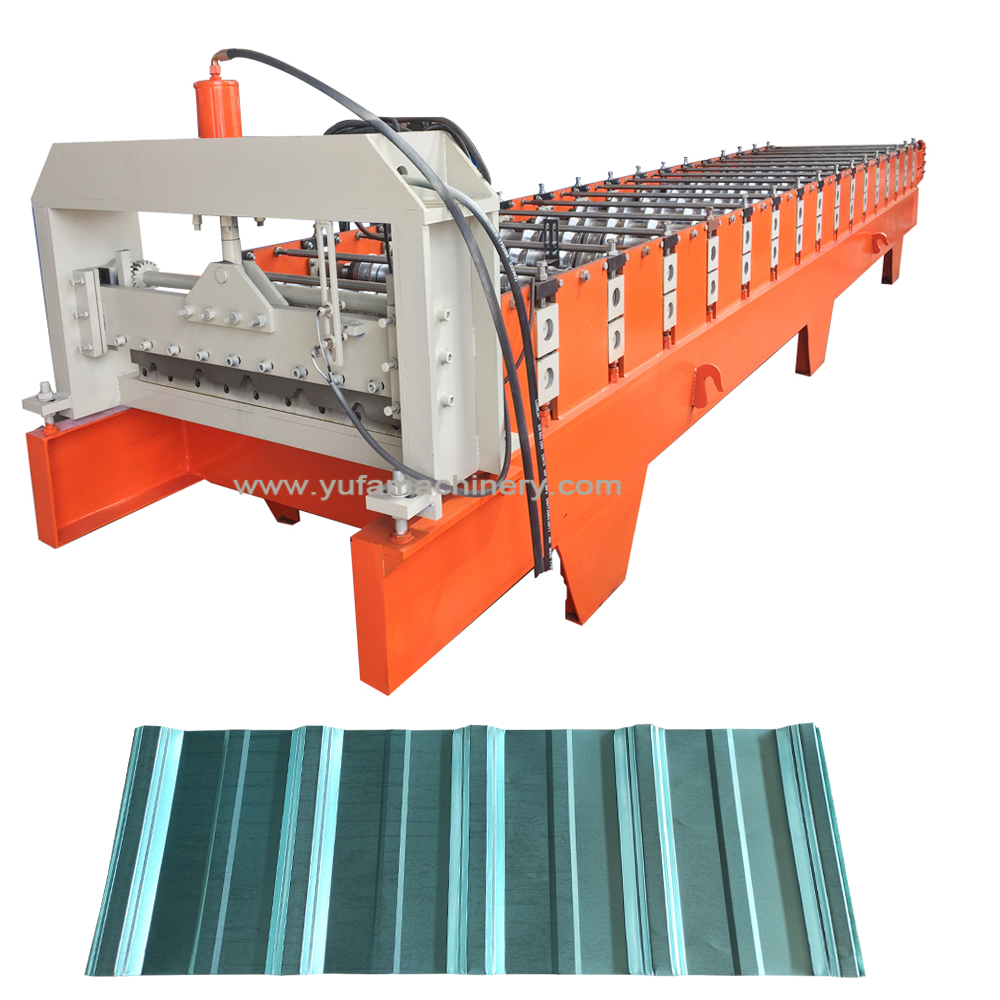

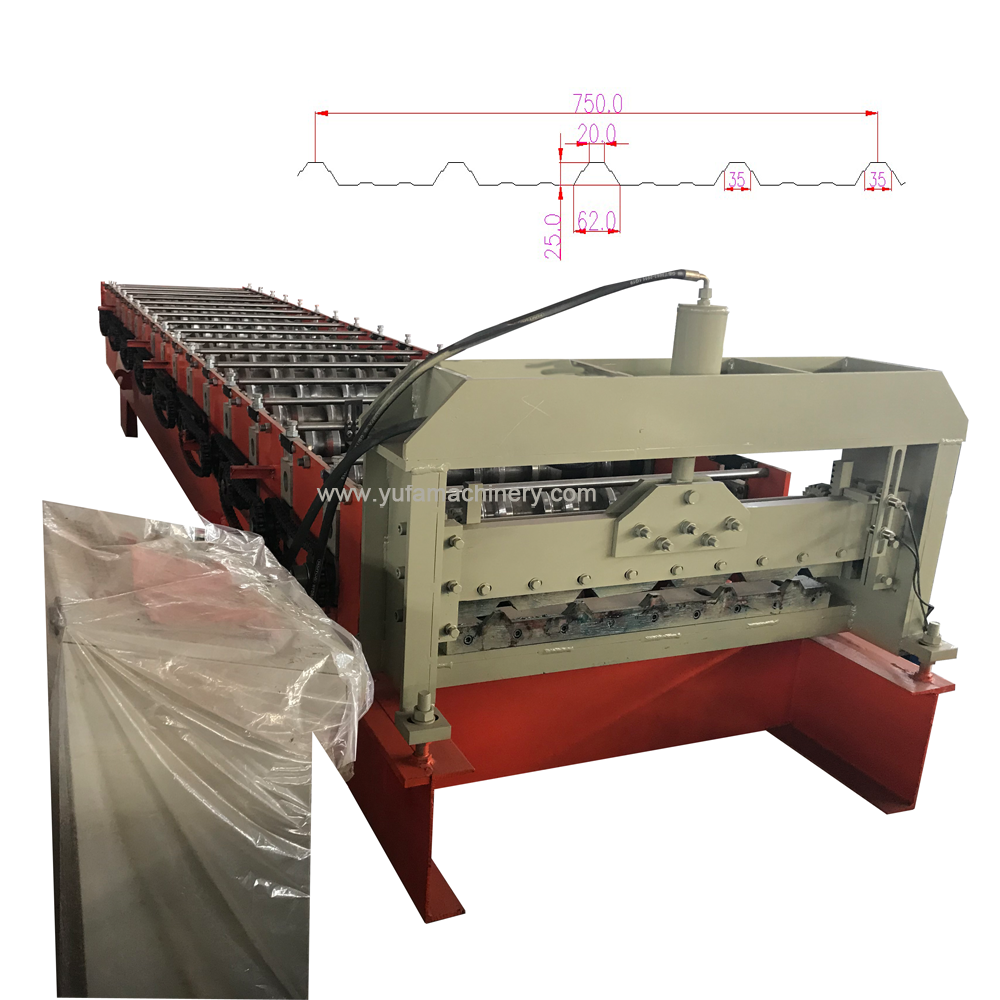

G550 hardness 750 spandek roll forming machine

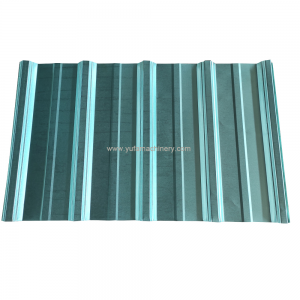

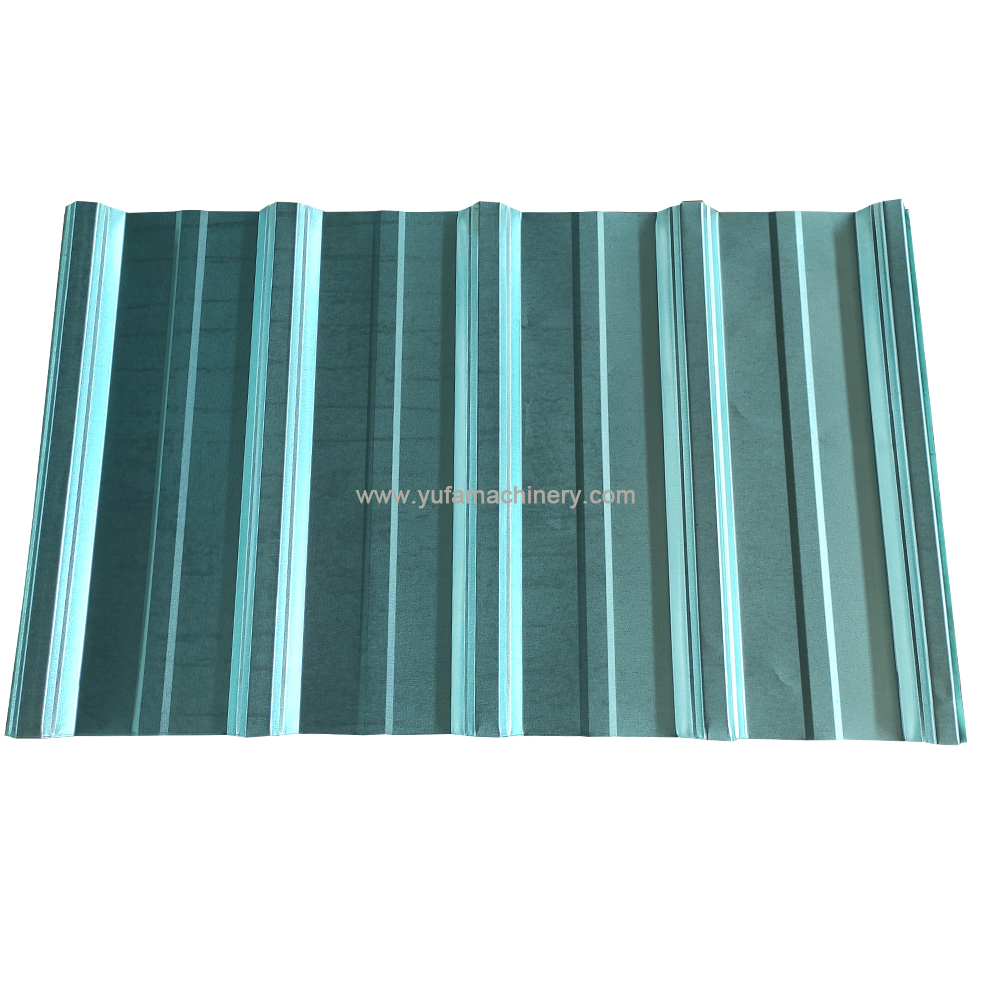

G550 hardness 750 spandek roll forming machine is popular used in Indonesia, Thailand, Vietnam and Malaysia. The hardness of the steel coil is G550 standard. The width of coil is 914mm.

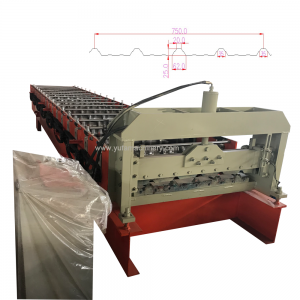

There is also kind of spandek roof machine named 1000 roof panel forming machine. The feeding width of coil is 1219mm. We supply 750 and 1000 mm width roof tile making machine for Southest countries for many years.

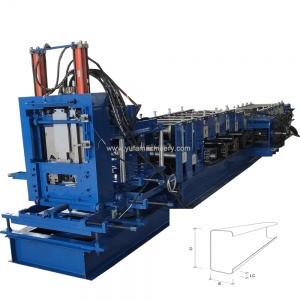

Hebei Yufa Tile Press Equipment Co.,Ltd can supply FORM E for roll forming machine clients. So the client can get discouented tax. Yufa company attend the exhibitions every year. We can meet with our clients in exhibition and canton fair. If needed roll forming machine, contact with us

Write your message here and send it to us