기계를 형성하는 강철 사다리꼴 형 지붕 타일 벽 패널 롤

스틸 사다리꼴 형 루핑 타일 벽 패널 롤 성형 기계

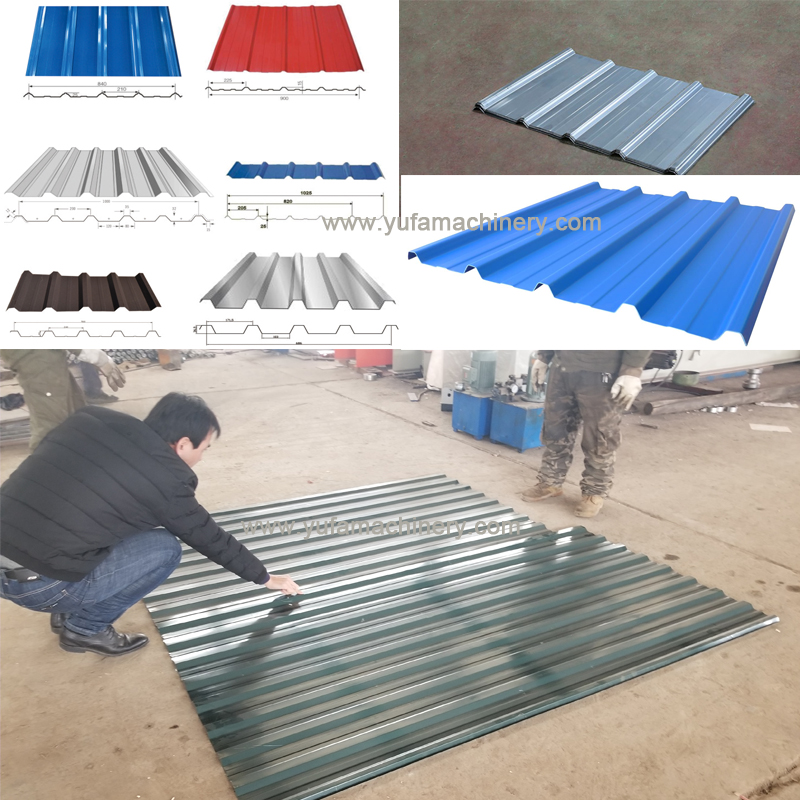

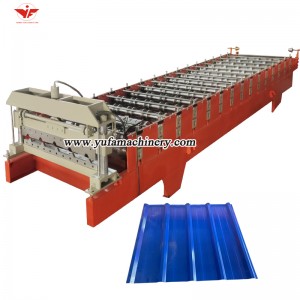

The coloured metal sheets produced by roofing tile wall panel 롤 성형 기계 look beautiful and modern .

그들은널리 정원, 센터와 빌라의 공장, 호텔, 전시, 지붕에 사용됩니다.

재료 :

먹이 폭 : 1,250mm

효과적인 폭 : 1,000mm의

두께 범위 : 0.3-0.8mm

입력 : GI & PPGI

Yiled 강도 : 235-345MPA

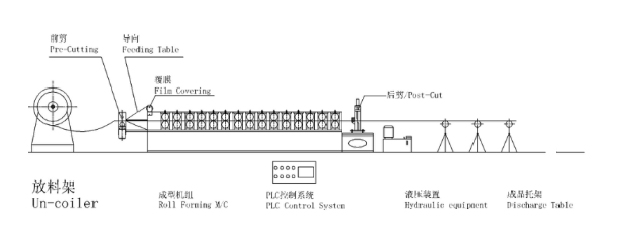

기계 작업 프로세스 :

부품에게 - 전기 컨트롤 박스를 형성하는 단계를 표 -Film 부분 - 자동 precutter을 Decoiler는 수유

-Hydraulic 자동 절단기 - 수신 테이블

기계 구성 요소 :

1) 수동 Decoiler

무게 capacaity 5t, 코일 폭 1,250mm. 그것은 유리 타일 지붕 기계의 코일을 지원합니다.

2) 부분을 먹이 :

이것은 기계 루핑 단계 TILS위한 먹이 중량 부이다. 사용 슬라이더 유형은 쉽게 조정하고 수정합니다. 또한

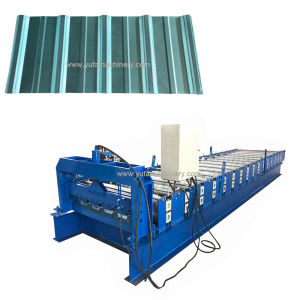

3) 성형 부품 :

이 부분 형성되어 유럽 표준입니다. 쉽게 고객이 조정을 위해, seprate 45mm 두께 스테이션 상자를 사용합니다.

강하고 훨씬 더 아름다운.

4) 유압 자동 커터 :

우리는 유럽 표준에 따라 포스트 가이드 형 커터 블레이드를 사용하여 업데이트됩니다.

여기에 메시지를 작성하여 보내주십시오